Inspect AI

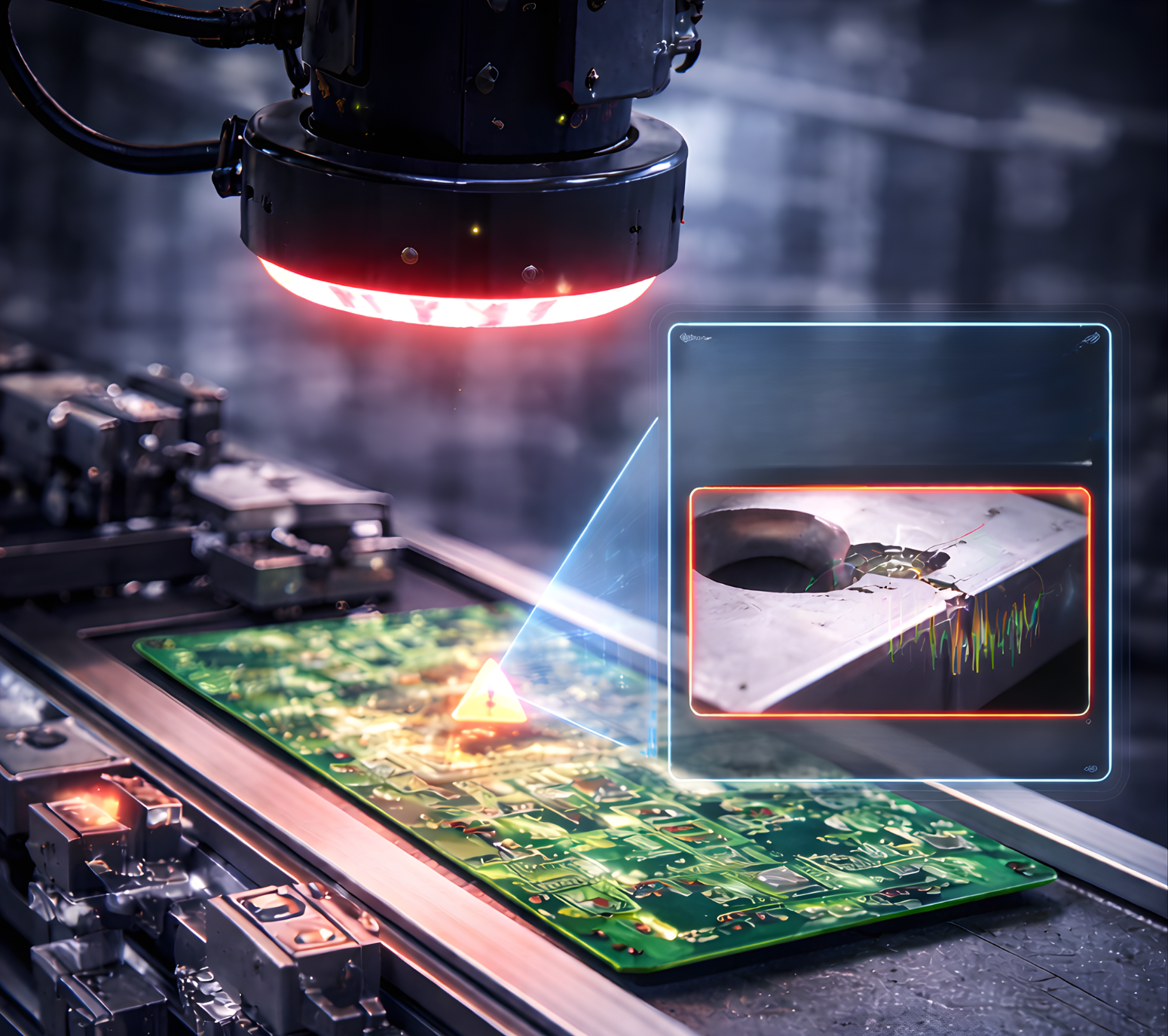

AI based Visual Inspection for Modern Manufacturing

- Automates process for inspection and creates records for audits, with full traceability across parts, batches, shifts, and machines.

- Explainable AI vision enables defect detection, Defect localization characterization for faster action.

- Eliminates the need for prior reference datasets and time-consuming customization steps that conventional solutions require, enabling defect detection without slowing down production.

- Enables a shift from reactive to predictive, preventive quality control, helping teams prevent repeat failures before they occur.

Use cases

Automate Manual Visual Inspection

Replace slow and inconsistent manual inspection with AI-driven, repeatable quality checks at lower inspection costs.

Remove Quality Bottlenecks from Production Lines

Prevent inspection delays that impact throughput and takt time.

Visual Proof and Traceability for Audits

Create time-stamped visual records linked to every part, batch, and line.

Defect History and Root-Cause Analysis

Analyze defect patterns across machines, shifts, batches, and parameters to pinpoint root causes.

Real-Time Quality Alerts for Operators

Trigger instant alerts to stop defect propagation before it spreads.

Scale AI Inspection Across Lines and Plants

Replicate inspection logic consistently across multiple lines and factory locations.

Reliable Inspection Under Real-World Conditions

Detects defects in different parts of the machine, or the same defect in different machines, or same defects in different factories.

Move from Reactive to Predictive Quality Control

Convert inspection data into preventive, forward-looking quality intelligence.