Challenges We Solve

Predictive Maintenance

Manufacturing operations are frequently disrupted by unplanned machine failures that impact uptime, yield, and delivery commitments. These issues are worsened by the inability to monitor and correlate vibration, temperature, current, pressure, and acoustics within a single intelligence system. Cloud-dependent monitoring introduces latency, connectivity risks, and data exposure, while rule-based thresholds fail to detect new and unseen failure modes as machines age. The high cost and scarcity of skilled maintenance experts further make manual condition monitoring unsustainable at scale.

Predict AI continuously analyzes machine behavior at the edge to predict failures before they impact operations, and eliminates unplanned breakdowns.

Vision in Low Light Conditions

Across surveillance, automotive, factories, and media pipelines, video systems often fail in low-light and night-time conditions, producing dark, blurry, and grainy footage. Object detection and analytics break down after dark, false alarms increase, and critical details like faces and license plates are missed, making footage unreliable for evidence. Outdoor environments add further challenges with glare, shadows, fog, and uneven illumination, requiring AI-based low-light enhancement and adaptive correction to maintain consistent visibility.

Fovea Clearity addresses these challenges by enhancing video feeds in real time at the edge, restoring clarity and creates day- like full colour images.Our zero shot variant is a true plug and play option reducing AI training and learning time significantly.

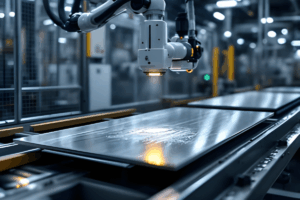

Defect Detection in Smart Factories

Manufacturing quality teams face bottlenecks caused by manual inspections and fragmented systems that slow audits, approvals, and containment actions. Without visual proof, traceability, and defect history, understanding why defects occur across batches, shifts, and machines becomes difficult. Traditional rule-based vision systems struggle with glare, shadows, lighting changes, and fail to detect new, unknown, and anomalous defects as products and processes evolve-leading to escapes, rework, and delayed decisions.

Inspect AI addresses these challenges by delivering real-time, edge-based visual inspection that automatically detects defects, creates visual records for audits, and enables faster, data-driven quality decisions.

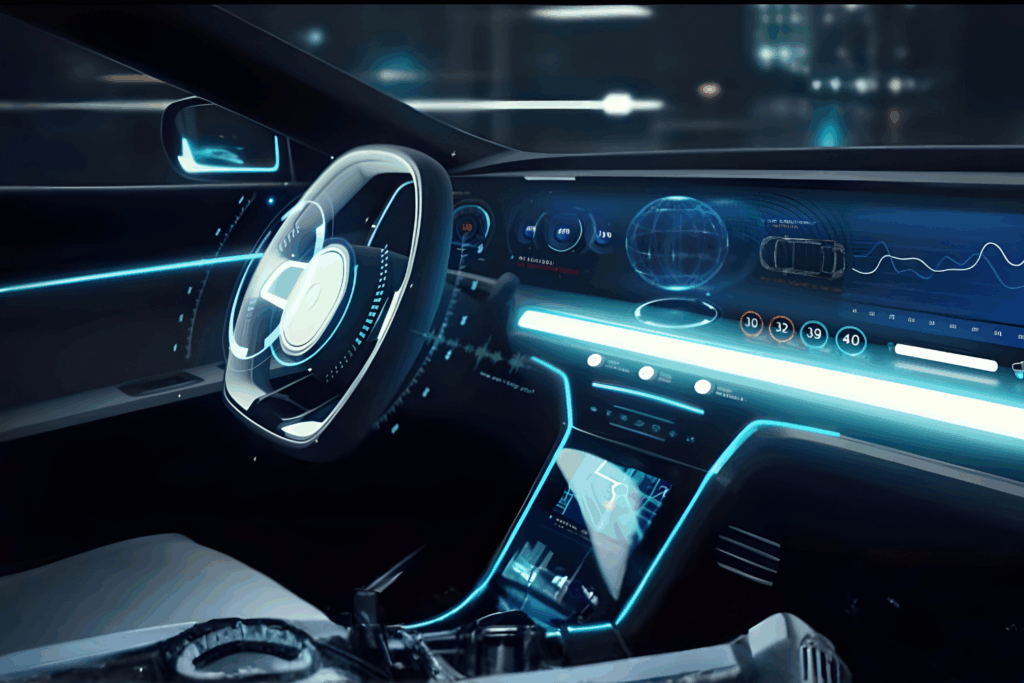

Automotive Digital Cockpit

In-vehicle systems struggle with unreliable connectivity, fragmented in-vehicle systems ecosystems, and lack of per-passenger intelligence, leading to frequent driver-passenger conflicts and distractions. Passengers repeatedly request changes to music, navigation, or cabin controls, turning the driver into a human interface and increasing safety risk*. Rear-seat experiences often feel inconsistent, children become restless on long journeys, and limited awareness of driver fatigue or alertness further impacts safety-highlighting the need for zero-touch, passenger-aware, voice-first in-cabin AI.

XAIRA transforms the in-cabin experience with agentic, passenger-aware AI that handles interactions seamlessly without pulling the driver into every request*.

*Upcoming features scheduled as part of our product roadmap.