Problems we solve

AI at the Edge, built for Automotive, Media, and Industrial transformation.

Security & Surveillance

Security and surveillance teams often struggle to achieve clear CCTV footage at

night, particularly in motel parking lots, gas stations, and outdoor parking areas,

where cameras produce dark, blurry, and grainy video. Percep Edge delivers AI-

powered low-light enhancement (LLE) combined with denoising, dehazing, and IR

optimization to improve night-time visibility. It enables dangerous object detection,

reduces false alarms during night surveillance, and enhances CCTV footage for

investigations and evidence. By adapting to glare, fog, headlights, and uneven

lighting, Percep Edge ensures reliable, always-on surveillance in real-world

environments.

Smart Factory

Factory surveillance systems often break down in low-light, dusty, or fog-prone

industrial settings, resulting in noisy footage, missed safety risks, and frequent false

alarms. Percep Edge improves industrial CCTV using AI-based low-light

enhancement, denoising, dehazing, and IR-aware processing, increasing visibility

across shop floors and perimeters. With dangerous object detection and anomaly

detection, it strengthens factory safety monitoring while reducing manual control-

room fatigue. The result is automated, consistent, and cost-effective surveillance

across factory sites.

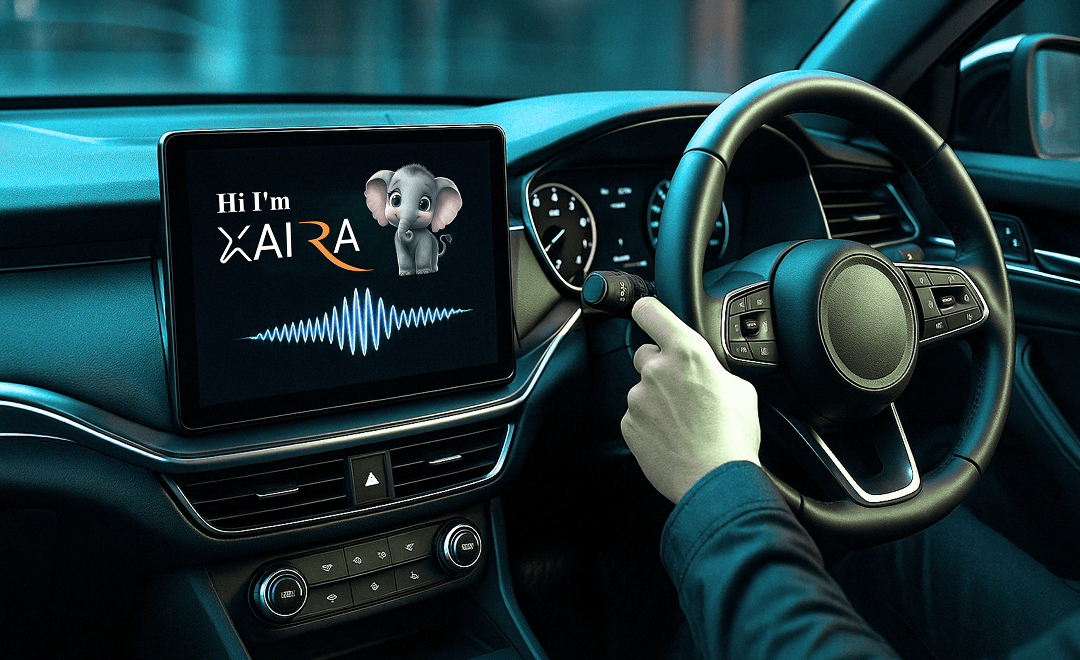

XAIRA

Smart Factory

Factory surveillance systems often break down in low-light, dusty, or fog-prone

industrial settings, resulting in noisy footage, missed safety risks, and frequent false

alarms. Percep Edge improves industrial CCTV using AI-based low-light

enhancement, denoising, dehazing, and IR-aware processing, increasing visibility

across shop floors and perimeters. With dangerous object detection and anomaly

detection, it strengthens factory safety monitoring while reducing manual control-

room fatigue. The result is automated, consistent, and cost-effective surveillance

across factory sites.

Predict AI

Smart Factory

Manufacturers often search for how to predict machine failure before it happens,

predictive maintenance for manufacturing machines, and how to prevent unplanned

downtime in factories. Predict AI addresses these challenges by correlating vibration,

temperature, current, pressure, and acoustics through multi-sensor machine

monitoring and integrated machine health intelligence. Using AI-driven anomaly

detection, it identifies unknown failure modes, early machine degradation, and

breakdown patterns that rule-based thresholds miss. Running as edge AI for

predictive maintenance, Predict AI enables low-latency, cloud-independent failure

prediction, reducing manual condition monitoring costs, expert dependency, and

improving machine health trend analysis and remaining useful life (RUL) prediction.

Blogs and Case studies

See our AI in action: Read stories, studies, and deep dives from the field.

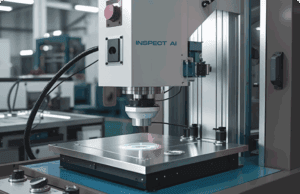

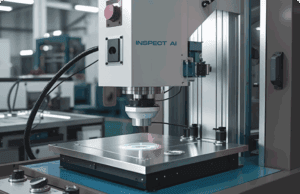

Read MoreInspect AI

Smart Factory (Primary Fit)

Manufacturing quality teams frequently look for how to automate visual inspection,

why manual inspection slows production, and AI-based quality inspection systems

that scale. Inspect AI replaces fragmented processes with automated visual

inspection that provides visual proof for quality audits, digital inspection records, and

end-to-end traceability. Powered by explainable AI vision, it enables root-cause

analysis for manufacturing defects, defect history analytics, and insight across

batches, shifts, and machines. Inspect AI maintains accuracy despite glare,

shadows, and lighting changes, while detecting unknown, anomalous, and evolving

defects beyond rule-based vision systems, enabling faster containment and

response.